Transformer Oil Tan Delta and Resistivity Tester

The Transformer Oil Tan Delta and Resistivity Tester is a cutting-edge device designed for precise analysis of transformer oil’s insulation properties. This tester is essential for assessing the dielectric strength and overall health of transformer oil, ensuring reliable and efficient operation of electrical equipment.

lizhvtesttech@gmail.com

+1 323 522 4623

Key Features:

- Comprehensive Testing: Capable of measuring both tan delta (dissipation factor) and resistivity of transformer oil, providing a complete picture of its insulating quality.

- High Accuracy: Advanced technology ensures precise and repeatable measurements, crucial for maintaining the integrity of your electrical systems.

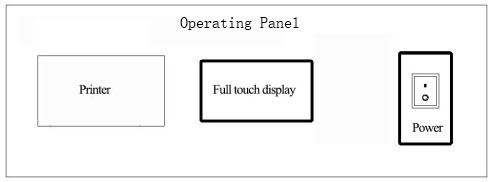

- User-Friendly Interface: Intuitive controls and a clear display make it easy for technicians to operate, even in challenging environments.

- Portable Design: Lightweight and compact, the tester is ideal for both laboratory and on-site testing.

- Rapid Results: Fast testing and analysis allow for quick decision-making, helping to minimize downtime and prevent potential failures.

Applications:

- Power Utilities: Essential for routine maintenance and monitoring of transformer oil condition in power plants and substations.

- Industrial Facilities: Ensures the reliable performance of transformers in manufacturing and processing plants by regularly checking oil insulation quality.

- Laboratories: Perfect for research and development labs focused on transformer oil analysis and quality control.

Technical Specifications:

Measuring Range:

- Electric Capacity: 5 pF to 200 pF

- Relative Permittivity: 1.000 to 30.000

- Dielectric Loss Factor (Tan Delta): 0.00001 to 100

- DC Resistivity: 2.5 MΩ·m to 20 TΩ·m

Measuring Accuracy:

- Electric Capacity: ± (1% of the measured value + 0.5 pF)

- Relative Permittivity: ± 1% of the measured value

- Dielectric Dissipation Factor: ± (1% of the measured value + 0.0001)

- DC Resistivity: ± 10% of the measured value

Resolution:

- Electric Capacity: 0.01 pF

- Relative Permittivity: 0.001

Oil Cup Technical Standards

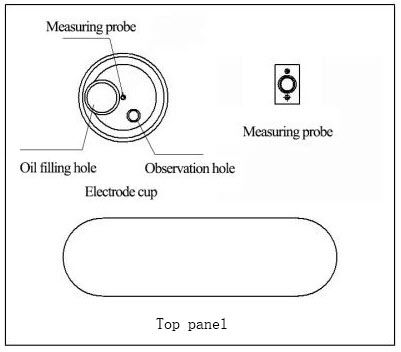

The test cell features a three-electrode structure compliant with the national standard GB/T5654-2007. It has an electrode gap spacing of 2mm, which effectively eliminates the effects of stray capacitance and reduces leakage during dielectric loss tests.

Specifications:

- Electrode Gap Spacing: 2mm (Distance between high voltage and low voltage electrodes)

- Dry Cell Capacitance: 60±5 pF

- Maximum Test Voltage (Power Frequency): 2000V

- Dry Cell Dielectric Loss (Tan δ): <1×10⁻⁴

- Liquid Capacity: Approximately 40ml

- Electrode Material: Stainless steel

- Dimensions: 70mm (Diameter) × 120mm (Height)

Handling the Test Cell

Loading the Test Cell:

- Carefully place the oil cup into the instrument furnace, ensuring good bottom contact.

- Connect the test line, inserting the test probe into the test sample cup.

Removing the Test Cell:

- After disconnecting the test line, the oil cup can be safely removed.

Dismantling and Assembling the Test Cell’s Electrode

The inner electrode can be directly removed from the oil cup. Attention: The inner electrode is a precision component. When removing or reinstalling it, handle it with care, avoiding any collisions between the internal and external electrodes to prevent surface damage or compromising the test cell.

Loading the Oil Sample

- Remove the inner electrode.

- Pour 40ml of the oil sample into the oil cup, taking care to avoid trapping air bubbles.

- Reinstall the inner electrode and let it sit for at least 15 minutes to allow any bubbles to fully dissipate before testing.

Cleaning the Test Cell

Proper cleaning of the oil cup before measurement is crucial due to the high sensitivity of insulating oil to contamination. Follow one of the methods below:

Method 1:

- Disassemble the oil cup electrodes.

- Wash with neutral soap or detergent, avoiding any abrasive actions that could damage the electrode surface.

- Rinse the electrodes multiple times with clean water.

- Soak the parts in anhydrous alcohol.

- After cleaning, dry the electrode surfaces with silk fabrics and store in a clean container.

- Place the parts in an oven at around 100°C to dry.

Method 2:

- Disassemble the oil cup.

- Clean all parts thoroughly with chemically pure petroleum ether and benzene.

- Rinse with acetone and neutral detergent.

- Boil the parts in a 5% sodium phosphate distilled water solution for 5 minutes, then rinse with distilled water.

- Dry the parts in an oven at 105 to 110°C for 60 to 90 minutes.

- Reassemble the parts when they cool to room temperature.

Method 3: Ultrasonic Cleaning:

- Disassemble the oil cup.

- Clean all parts with solvent.

- Place all parts in soapy water and oscillate for 20 minutes using an ultrasonic cleaner.

- Rinse with tap water followed by distilled water, and then oscillate with distilled water for another 20 minutes.

Method 4: Solvent Cleaning:

- Disassemble the oil cup.

- Rinse all parts with solvent, replacing the solvent as needed.

- First wash with acetone, followed by tap water, and then with distilled water.

- Dry the parts in an oven at 105 to 110°C for 60 to 90 minutes.

When testing a series of similar liquid samples, the same test cell may be used without intermediate cleaning, provided the previous sample tested had a performance better than the specified measuring value. If a tested sample’s performance is inferior, the test cell must be cleaned before conducting the next test.

Why Choose Our Transformer Oil Tan Delta and Resistivity Tester?

- Reliable Performance: Delivers consistent and accurate results, helping you maintain the safety and efficiency of your electrical equipment.

- Comprehensive Support: Backed by our expert technical support team, ready to assist with any queries or technical issues.

- Cost-Effective Solution: Offers high-quality testing capabilities at a competitive price, making it an excellent investment for long-term equipment reliability.

Contact Us:

Ensure the optimal performance of your transformers by regularly testing the insulation properties of transformer oil with our Transformer Oil Tan Delta and Resistivity Tester. Contact us today for more information or to request a quote. email: Sale@hvtesttech.com or call us: +1 323 522 4623